Our premium abrasive tumbling media, vibratory finishing media, and barrel tumbling & deburring services deliver consistent, high-quality surface finishing results for metal parts, components, and manufactured goods. Engineered for durability and optimal performance in vibratory finishing, barrel tumbling, and centrifugal disc applications. Tumbling Media includes Ceramic Tumbling Media, Plastic Tumbling Media, and Steel Tumbling Media.

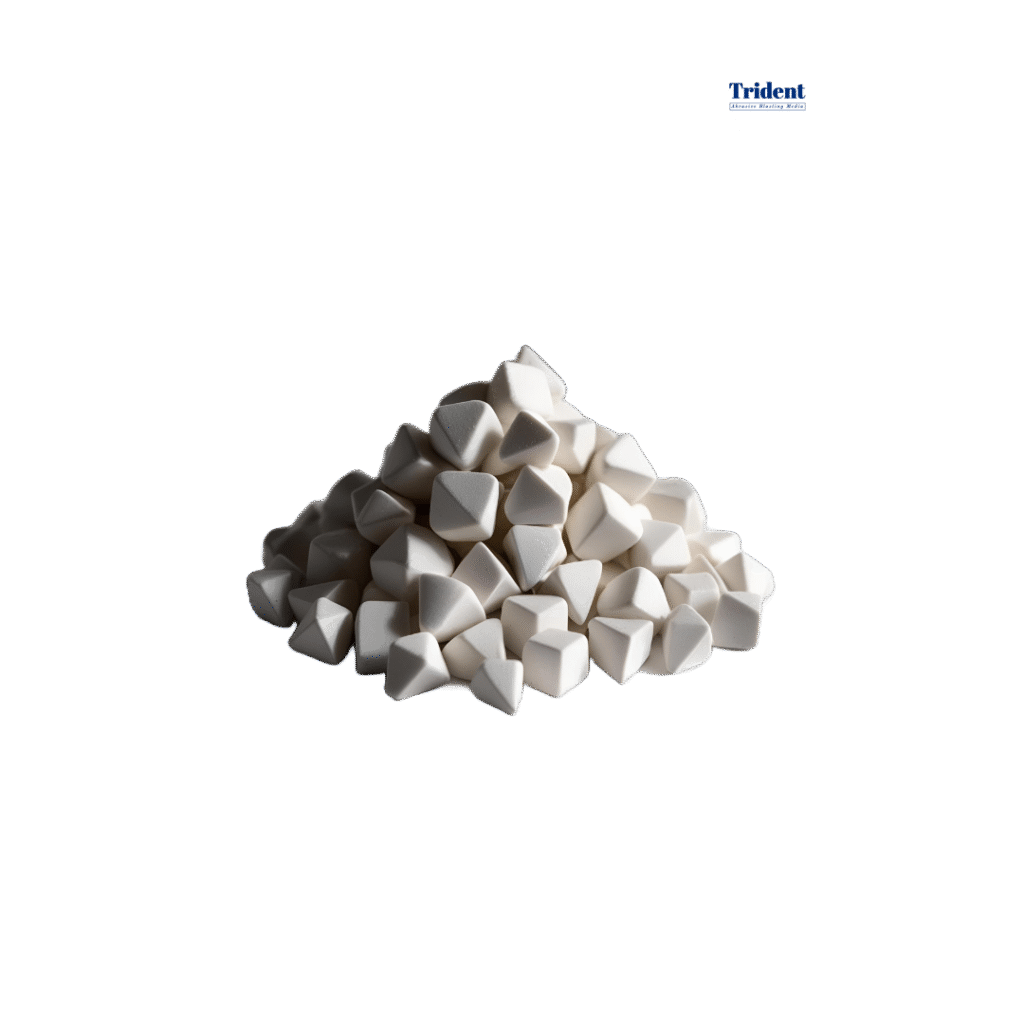

Ceramic Tumbling Media

Trident Abrasive offers high-performance ceramic tumbling media designed for precision deburring, surface smoothing, and polishing in vibratory and rotary tumblers. Manufactured from premium ceramic materials and engineered for consistent performance, our media is ideal for finishing metal parts with tight tolerances, delivering clean, uniform results across a wide range of industries.

Key Features:

- Durable & Long-Lasting: High-density ceramic formula ensures extended media life and low wear rates, even in aggressive applications.

- Superior Cutting Power: Engineered for fast material removal while maintaining dimensional accuracy.

- Multiple Shapes & Grades: Available in a variety of shapes (triangles, cylinders, cones, etc.) and abrasive grades (coarse, medium, fine) for customized results.

- Low Dust & Clean Finish: Low-residue formula reduces contamination and keeps finishing systems cleaner.

- Safe for Metal & Non-Metal Parts: Suitable for steel, aluminum, brass, zinc, and plastic components.

Technical Specifications

| Specification | Value |

| Material | High-density aluminum oxide ceramic |

| Shape | Equilateral triangle |

| Size | 1/2″ x 1/2″ x 1/2″ |

| Grit | 220 (medium cutting) |

| Bulk Density | 2.1 g/cm³ |

| Hardness | 8 Mohs scale |

| Color | Natural brown |

| Operating Temp | -20°F to 180°F |

Applications & Uses

- Heavy deburring of machined parts

- Internal surface finishing in complex geometries

- Edge breaking on sharp corners

- Pre-plating surface preparation

- Automotive components – engine blocks, transmission parts

- Aerospace parts – brackets, housings, fittings

Processing Parameters

- Media to parts ratio: 3:1 to 4:1 by volume

- Typical cycle time: 45-90 minutes for deburring

- Recommended compound: Medium cutting compound at 2-3%

- Water level: Cover parts and media completely

Packaging: 25kg bags | 1-ton bulk bags | Custom packaging available upon request

Plastic Media

Our plastic tumbling media is a high-performance finishing solution designed for precision deburring, surface smoothing, and polishing of soft metals, plastics, and delicate components. Manufactured from durable polyester resins and blended with abrasives, it provides consistent results while preventing part damage or distortion.

Ideal for use in vibratory and barrel finishing machines, Trident Abrasive’s plastic media delivers clean, uniform finishes without scratching or warping sensitive materials.

Key Features :

- Lightweight & Non-Aggressive: Safe for soft metals like aluminum, brass, and zinc, as well as plastic and die-cast parts.

- Low Wear on Parts & Equipment: Reduces the risk of part impingement, edge rounding, or machine wear.

- Excellent Media Retention: Precision-formed shapes provide consistent tumbling action and effective surface contact.

- Available in Various Shapes & Sizes: Triangles, cones, pyramids, and cylinders for optimized processing.

- Fast Processing Time: Speeds up finishing cycles while maintaining quality surface results.

Technical Specifications

| Specification | Value |

| Material | Polyester resin with abrasive grit |

| Shape | Four-sided pyramid |

| Size | 1/2″ base x 3/8″ height |

| Grit | Medium cutting (equivalent to 180 grit) |

| Bulk Density | 1.1 g/cm³ |

| Color | Green, Blue |

| Chemical Resistance | Excellent |

Applications & Uses

- Light deburring of machined parts

- Precision component finishing

- Zinc die casting cleanup

- Electronic component preparation

- Medical device finishing

- Jewelry and decorative items

Processing Recommendations

- Media to parts ratio: 4:1 to 6:1 by volume

- Typical cycle time: 60-180 minutes

- Compound selection: Mild cutting or cleaning compounds

- Temperature range: 60°F to 140°F for optimal performance

Packaging: 25kg bags | 1-ton bulk bags | Custom packaging available upon request

Walnut Shell

Trident Abrasive’s walnut shell abrasive media is a biodegradable, natural blasting solution made from crushed walnut shells. Lightweight yet effective, this organic media is ideal for delicate cleaning, polishing, and deburring without damaging underlying surfaces. Commonly used for applications where preserving part integrity is critical, walnut shell grit is a versatile and environmentally safe alternative to traditional abrasives.

Key Features

- Non-Toxic & Eco-Friendly: 100% natural and biodegradable, safe for both operators and the environment.

- Gentle Yet Effective: Removes paint, grease, carbon, and coatings without harming metal, wood, plastic, or composites.

- Low-Dust & Reusable: Reduces cleanup time and can be reused multiple times, enhancing cost efficiency.

- Lightweight Material: Ideal for soft blasting applications where minimal surface impact is required.

- Customizable Sizes: Available in a variety of mesh sizes for specific finishing requirements.

Technical Specifications

| Specification | Value |

| Material | Ground walnut shells |

| Mesh Size | 12/14 (medium grade) |

| Bulk Density | 0.8 g/cm³ |

| Hardness | 3-4 Mohs scale |

| Moisture Content | <5% |

| Oil Absorption | 2x its weight |

| pH Level | Neutral (6.5-7.5) |

| Color | Natural tan/brown |

Primary Applications

- Brass cleaning and restoration

- Plastic part finishing

- Oil absorption from machined parts

- Paint stripping (light applications)

- Jewelry polishing

- Antique restoration

Packaging: 25kg bags | 1-ton bulk bags | Custom packaging available upon request

For safe handling and workplace practices when using tumbling media, please review the official OSHA Safety Guidelines