Discover the benefits, uses, and eco-friendly properties of crushed glass. A safe, efficient, and sustainable blasting media for industrial and commercial applications.

In the world of surface preparation and industrial blasting, it is quickly becoming the preferred choice. Derived from 100% recycled glass, this media is not only effective but also environmentally responsible. Whether you’re removing rust, paint, or corrosion, crushed glass offers a clean, sharp, and dust-reducing performance compared to traditional abrasives.

What is Abrasive Crushed Glass?

Crushed glass is a high-performance, eco-friendly abrasive media made from 100% recycled glass. With sharp, angular particles, it delivers aggressive cleaning and coating removal while producing minimal dust. Free from crystalline silica, it’s a safer choice for workers and ideal for industrial blasting, automotive restoration, and marine maintenance. Available in multiple grit sizes for precise surface preparation, crushed glass ensures consistent results and supports sustainable blasting operations.

1. Environmentally Friendly and Sustainable

Made from 100% recycled glass bottles, crushed glass abrasive helps reduce landfill waste and promotes a circular economy. By repurposing post-consumer glass, it supports eco-conscious blasting practices without compromising on performance. For businesses aiming to reduce their environmental footprint, crushed glass is a responsible choice.

2. Silica-Free for Safer Work Environments

Unlike traditional sand, crushed glass is free from crystalline silica, a known respiratory hazard. This means reduced health risks for operators and a safer workplace that aligns with occupational safety standards. Lower dust generation also improves visibility during blasting, boosting overall productivity.

3. Aggressive Cleaning Power

The angular, sharp-edged particles of crushed glass cut through rust, coatings, and contaminants quickly and effectively. This makes it ideal for heavy-duty applications such as marine vessel maintenance, industrial equipment refurbishment, and automotive bodywork restoration.

4. Versatile Surface Preparation

Crushed glass is available in multiple grit sizes, allowing you to achieve the exact surface profile required for your project. Whether you need a light etch for painting or a deep profile for heavy coatings, it adapts to a wide range of blasting requirements.

5. Cost-Effective and Efficient

While crushed glass is a single-use abrasive in most cases, its cutting speed can reduce blasting time, saving on labor costs and project turnaround. Its ability to clean surfaces thoroughly in fewer passes makes it an economical option for both small workshops and large-scale operations.

6. Gentle on the Base Surface

Despite its aggressive cleaning action, it is less likely to embed in the blasted material or warp thin metal surfaces. This makes it suitable for applications where preserving the integrity of the underlying surface is essential.

7. Reduced Waste and Easy Disposal

Since crushed glass is non-toxic and made from inert materials, it’s generally easier to dispose of compared to other abrasives that may contain hazardous elements. This simplifies cleanup and disposal, reducing environmental compliance costs.

Common Applications

– Rust and Paint Removal

– Surface Preparation for Coatings

– Graffiti Removal

– Concrete Texturing and Cleaning

– Restoration Projects

Grit Sizes Available

It is available in a wide range of grit sizes, including:

– Fine (40/70)

– Medium (20/40)

– Coarse (10/20)

Each size is tailored to specific applications, from gentle cleaning to aggressive blasting

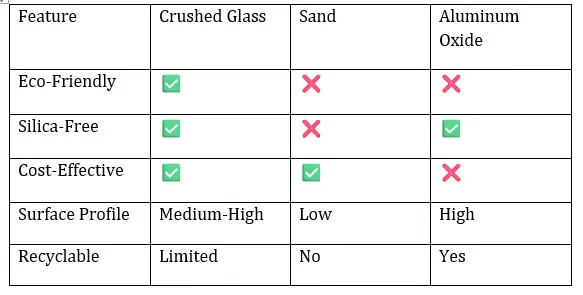

Why Choose Over Other Media

Making a Difference

Every glass bottle or jar that gets recycled instead of thrown away contributes to this sustainable cycle. By choosing products made with recycled glass content and properly recycling our glass waste, we all play a part in supporting this environmentally friendly industry.

Crushed glass represents more than just recycling—it embodies the principles of sustainability, innovation, and resourcefulness. In a world increasingly concerned with environmental impact, this sparkling material shines as a beacon of how waste can be transformed into something valuable, beautiful, and beneficial for our planet.

Whether it’s strengthening the concrete in our buildings, filtering our water, or adding sparkle to artistic creations, crushed glass proves that sometimes the most discarded materials can become the most valuable resources.

Final Thoughts

If you’re searching for an abrasive media that checks all the boxes—performance, safety, sustainability, and cost-efficiency—abrasive crushed glass is your answer. It’s a forward-thinking solution for industries committed to cleaner and greener operations.

Trident Abrasive supplies premium-quality crushed glass in various grit sizes and with different packaging options, ensuring reliable, efficient, and cost-effective results for every blasting project.

Please visit www.tridentabrasive.com or our products for more information.